Each

business day many companies throw away a valuable corporate asset, the

history of production. The PI System fully automates the collection,

archiving

and dissemination of this information.

Process

and plant data are the foundation of many business decisions. This

information

must be available to everyone, unfiltered and when needed. The PI

System

provides a fully automated package to collect, store, present and

distribute

plant data. Convenient and fast data access can significantly reduce

the

time required to make critical quality, cost, safety and environmental

decisions. The direct access to validated and timely plant information

also improves decision-making and performance. The PI System by OSI

Software

makes all this happen in a wide range of industries, every day.

PI has

the largest installed base of any Plant Information Management System.

The PI System features an open client/server architecture that delivers

data to the desktop, while preserving data security. The PI System Data

Archive stores all the plant data on-line for years, and a wide variety

of tools for exchanging data with other systems are supported. Whether

you call it a Millwide Information System, a Refinery Information

Management

System, a Plantwide System, MES, or enterprise-wide computing, PI is an

enterprise wise way to gain process knowledge; one that is remarkable

easy

to use, implement and manage.

Hundreds

of companies worldwide rely on the PI System for continuous improvement

of plant performance, product quality and customer service. To replace

a legacy system, build a new plant information system, or integrate a

variety

of process software applications, the PI System is the answer.

In today's

competitive environment, manufacturers are expected to make higher

quality

products with faster delivery, lower prices, fewer emissions and less

waste.

Here are some examples of how companies are using the PI System to meet

these increasingly difficult demands:-

Lower

Productions Costs

The

PI System's data analysis and graphical tools permit problems to be

resolved

faster, and often prevent small conditions from becoming major upsets.

Many companies report that the data stored in PI allow them to improve

their preventive maintenance programs, increasing equipment life. These

uses result in increased production and lower operating costs. In

addition,

the PI System contributes to yield improvements and less waste. When

the

lab system sends messages to operations via the PI System, for example,

the time required to change grades decreases, increasing production and

minimizing waste.

Higher

Product Quality

The

time to respond to a quality problem is before the product goes out of

spec. Applications such as the PI-Profiles package allow

inconsistencies

to be noticed and fixed before they become serious problems. Operators

also appreciate the PI System because they can review operating

conditions

from previous runs, a valued feature when producing unusual or

difficult

product grades. The PI System provides an easy-to-use mechanism for

obtaining

and monitoring continuous process improvement. These programs

frequently

lead to improved product quality with no increases in production costs.

Better

Customer Service

With

access to a PI System, customer service and quality assurance groups

can

quickly respond to customer complaints and concerns about product

quality.

This is because process data are stored at high resolution and remain

on-line

for extended periods of time. Personnel are also able to analyze past

data

to determine whether requests for new grades or product specs are

feasible.

And, because current data are also available, sales teams can review

process

conditions to determine when a new order can be scheduled or delivered.

Increased

Productivity and Improved Process Knowledge

Less

time is wasted trying to obtain data and information relating to a

problem,

so more time is available for solving it. Everyone throughout the

facility

uses a common set of data, eliminating discussions of whose data set is

"right", again contributing to a more productive use of everyone's

time.

Also, applications developed internally with the PI System, such as

performance

monitoring and efficiency calculations may be shared between sites,

reducing

development time.

Simplified

Environmental Reporting

Having

one system containing all the process data from a facility makes it

easier

to comply with environmental, health and safety regulations. In

addition,

the calculations enable inferred values to be used in lieu of

unreliable

measurement points. PI System users are able to meet many of these ever

changing requirements with a package that also helps them improve their

process and lower their costs.

|

|

The

PI SystemTM is a client/server based software program

designed to fully automate the collection, storage and presentation of

manufacturing plant data. PI employs a flexible architecture that can

be

implemented in a variety of system configurations.

The PI

Data Server provides centralized collection of information, a real-time

database and a historical data archive. PI client software packages put

the maximum amount of information processing power possible in the

hands

of the user. These clients, which include PI-DataLinkTM

and PI-ProcessBook®, allow the user to work in

the

familiar Microsoft® WindowsTM

environment.

Each

PI System can interface to one or more real-time systems simultaneously

and can read and write to virtually any real-time device or database.

Integration

tools, which include ActiveX controls, ODBC, and a large set of

application

programming interfaces, can be employed over the internet or in more

traditional

programming environments.

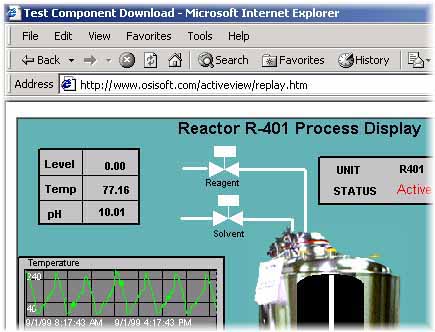

PI-ProcessBook®

Real-time

and/or historical plant data can be displayed in PI-ProcessBook by

creating

process graphics, trends, statistical plots and tables. PI-ProcessBook

is an ActiveX control container, features embedded Visual Basic for

Applications

(VBA) and is an ODBC container that enables users to easily combine

data

from PI and other databases on the same trend or display.

PI-ProcessBook

is an ideal platform for integration efforts. Data may be displayed in

a variety of formats, including process graphics, trends, statistical

plots,

tables and charts. Displays are easy to configure and may be created in

advance or built as desired. The same displays may be used for current

or historical data, and may be accessed by anyone connected to the

plant

network via PCs or workstations.

PI-DataLinkTM

PI-DataLink

provides an easy-to-use live link between the PI System and

spreadsheets.

The PI-DataLink add-in provides pull-down menu functions for accessing

real-time or historical data. PI-DataLink is a popular way to create

production

reports and to analyze process data. Users do not need to login to the

server and no special procedures are required. Add-in functions and

dialogue

boxes allow users to quickly access real time or historical data.

Customers

continue to use previously configured spreadsheets, but no longer need

to input data or use complex data import procedures.

PI-BatchViewTM

PI-BatchView

is a client application that allows PI customers to view data from a

batch-oriented

perspective. The PI-BatchView add-in to PI-ProcessBook supports

trending

data by batch; and the PI-DataLink add-in enables spreadsheet analysis

by unit, product and Batch ID.

PI-ActiveViewTM

PI-ActiveView

brings your PI-ProcessBook applications to the web. PI-ProcessBook

displays

run without modification because PI-ActiveView uses Microsoft's Visual

Basic for Applications and can take advantage of embedded ActiveX

controls.

PI-Data

ArchiveTM

PI

Systems

are designed to accommodate very large real-time and historical

databases,

with every process point stored on-line for years, to very near its

original

resolution. Plant or corporate-wide PI Systems can employ multiple data

archives. Data archives can be implemented in different system sizes

ranging

from 1,000 tags to over 100,000 tags.

PI-ODBC

PI-ODBC

makes the PI-Data Archive appear and act like a set of relational

tables.

PI-ODBC is frequently used to supply summary data such as Averages,

Minimums,

Maximums and Totals. Retrieval is very fast and the hazards of data

duplication

are eliminated.

PI

System Interfaces

The

data stored in PI can be generated by Distributed Control Systems

(DCS),

Programmable Logic Controllers (PLC), Lab Systems, SCADA Systems, via

manual

recording and by numerous other sources. Over 300 interfaces to common

information systems are available to transfer data to and from PI. A

single

PI System can include many interfaces, permitting data from several

control

systems or process areas to be combined and available throughout the

facility.

Sigmafine

Sigmafine has

been

licensed to over 100 sites worldwide. Many technologies and methods are

required to properly generate a set of reconciled data for a process

plant.

The knowledge from development and installation process of previous

Sigmafine

sites is used for continuous improvement.

An accurate

source of information

is essential to the profitability of a process plant. Plant data is the

basis for any form of numerical analysis. With the increasing use of

automation,

operational data becomes much more accessible to the users. However,

this

data is commonly imperfect. It often shows little consistency between

different

process units. Missing product flows, unaccounted material losses and

equipment

down time, reflect gross metering errors.

Sigmafine

represents a new-generation

Windows-based data reconciliation and yield accounting application. It

allows the site to more accurately analyze the quality of flow and

inventory

measurements and produce a single consistent set of the most accurate

reconciled

data possible.

For more product information and downloads

Contact

us today

TEKNIK

SEGALA SDN BHD

No

32

Jalan Bandar 13, Pusat Bandar Puchong

47160

Puchong, Selangor, MALAYSIA

Tel: +60 (03) 5882 6777 Fax: +60 1700 810 533

|

TEKNIK

SEGALA SDN BHD

TEKNIK

SEGALA SDN BHD MALAYSIA

MALAYSIA TEKNIK

SEGALA SDN BHD

TEKNIK

SEGALA SDN BHD MALAYSIA

MALAYSIA